Yale researchers developed a catalyst-free pyrolysis reactor that converts plastic waste into fuel with record efficiency, offering hope in the plastic crisis.

The world produces hundreds of millions of tons of plastic every year, yet only a small fraction is recycled. A team at Yale University has developed a new method of turning plastic waste into usable fuel without relying on expensive catalysts. Their 3D-printed reactor achieved a record 66 percent yield from polyethylene, a common type of plastic. While the breakthrough is promising, some critics question whether pyrolysis, the process at the heart of this method, can ever offer a true solution to the global plastic crisis.

- SUMMARY

- The world generates 460 million metric tons of plastic annually, with only 9% recycled.

- Pyrolysis, a process that breaks down plastic into fuel, has long been hindered by high energy demands and expensive catalysts.

- Yale researchers have developed a 3D-printed, catalyst-free reactor that achieves a record 66% yield from polyethylene.

The world generates about 460 million metric tons of plastic every year, but only around nine percent of it is ever recycled. The rest contributes to a growing crisis, leaving plastic waste scattered from the depths of the Mariana Trench to inside the human body. As the problem worsens, researchers are racing to find more effective ways to recycle plastic and reduce its environmental footprint.

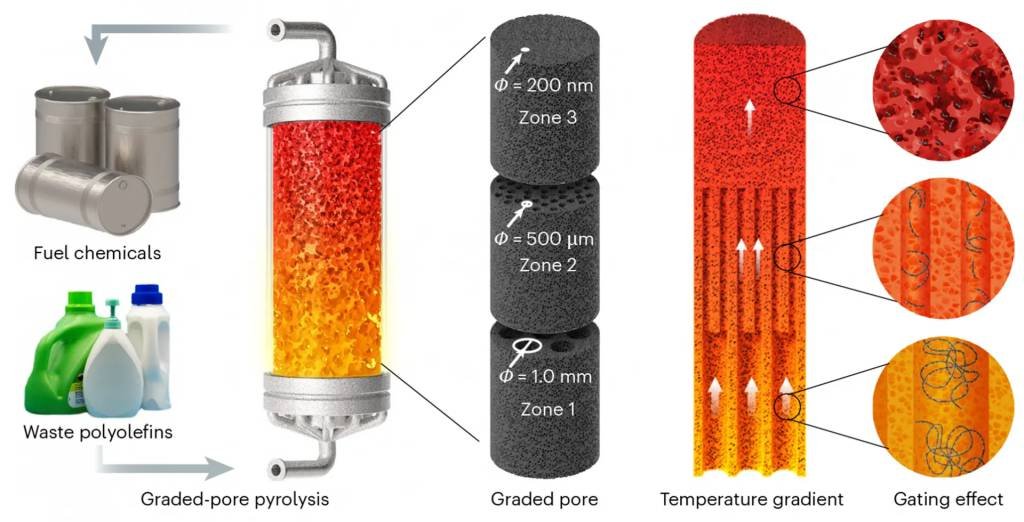

One of the most promising methods is pyrolysis, a process that uses high heat in an oxygen-free environment to break plastics back down into reusable hydrocarbons. In theory, pyrolysis could transform plastic waste into fuels and other valuable chemicals. In practice, though, the process is hampered by its enormous energy demands and the reliance on expensive chemical catalysts, which quickly degrade and add prohibitive costs.

Researchers at Yale University believe they may have found a way around these barriers. The team developed a 3D-printed reactor that can convert polyethylene, a common plastic, into fuel with unprecedented efficiency, all without using a catalyst. In experiments, their device converted about 66 percent of the plastic into useful fuel chemicals.

The study was led by Yale Engineering professors Liangbing Hu and Shu Hu, both members of the Center for Materials Innovation and Yale Energy Sciences Institute.

“Whenever you talk about catalysts, they’re very expensive, and you have a lifetime issue because catalysts will eventually die by different means,” said Liangbing Hu, the Carol and Douglas Melamed Professor of Electrical and Computer Engineering and Materials Science at Yale. He explained that finding a catalyst-free approach that is still efficient has been a major challenge in the field.

The breakthrough comes from the reactor’s design. Built from carbon and heated electrically, it contains three sections of pores that decrease in size as the material passes through. The first section has pores about one millimeter wide, the second has 500-micrometer pores, and the third narrows to just 200 nanometers. This layered structure helps control how the chemical reactions unfold, ensuring that larger molecules are fully broken down before moving forward.

To test whether the technology could be scaled up, the team also built a version of the reactor using carbon felt instead of 3D printing. While this version was slightly less efficient, it still converted 56 percent of the plastic into fuel, which is better than most traditional pyrolysis systems.

“These results are very promising and show a great potential for putting this system into real-world applications and offering a practical strategy for converting plastic waste into valuable materials,” said Shu Hu, assistant professor of chemical and environmental engineering at Yale. He co-authored the study, which was published earlier this year in Nature Chemical Engineering.

Even so, pyrolysis remains controversial. Environmental advocates have long warned that it may not deliver on its promises, and some critics see it as little more than an industry distraction. Last year, the nonprofit news outlet ProPublica reported that the plastics industry often exaggerates the effectiveness of pyrolysis, arguing that the technology is more of a “fairy tale” than a solution.

The Yale project involved collaborators from Purdue University, the University of Delaware, Missouri University of Science and Technology, West Virginia University, the University of Wisconsin–Madison, Princeton University, and the National Renewable Energy Laboratory’s BOTTLE Consortium. While questions remain about the role pyrolysis can realistically play in addressing plastic waste, the researchers believe their work represents a meaningful step toward turning plastic waste into useful resources.

Have a news or topic to share with industry? Write to us editorial@pfionline.com