Bakery specialists can now craft eggless muffins, cakes, and other bakery products, using a next-gen clean-label texturizer pea protein to replicate the function and flavor of eggs in baked goods, thanks to the new Lasenor® VP-100 formulation.

Barcelona, December 2025: Bakery solutions specialist Lasenor Emul, S.L. has successfully developed high-quality muffins formulated with 50-100% less egg, without compromising sensory appeal or functionality. The company introduced Lasenor® VP-100, a clean-label, texturizing pea protein, during its official launch at Fi Europe 2025. The hybrid baked products were showcased to demonstrate the ingredient’s performance in commercial bakery applications.

New Partnership Strengthens Innovation Pipeline

Lasenor® VP-100 is a texturizing pea protein specifically designed for industrial bakery formulations. The ingredient is the result of a collaboration between Lasenor and ingredient technology innovator Meala FoodTech, Ltd. Developed using Meala’s proprietary texturization technology, the single-ingredient protein was further optimized by Lasenor to perform effectively in aerated batter systems commonly used in cakes and muffins.

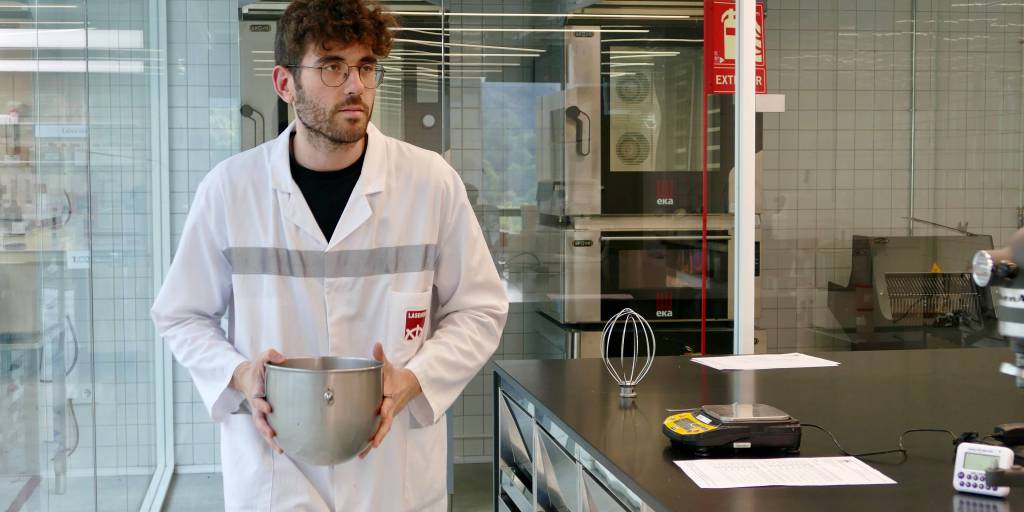

New Technical Center and Bakery Laboratory

Lasenor has also inaugurated a new technical center featuring a fully equipped bakery laboratory. The facility is dedicated to supporting industrial bakery manufacturers, including cake mix producers, in the development of plant-based bakery concepts that meet expectations for taste, texture, and functionality.

“Our customers can test recipes, optimize processes, and validate product performance under real manufacturing conditions,” explains Chiara Marinanza, Marketing Director at Lasenor. “They also benefit from our application expertise, formulation know-how, and direct access to the bakery market. This service reinforces Lasenor’s position as an application-driven partner rather than just an ingredient supplier.”

Enabling 50–100% Egg Replacement

Lasenor® VP-100 was designed specifically for bakery use, delivering enhanced aeration, a softer crumb, and extended freshness by slowing the staling process. The ingredient functions as a single-solution texturizer, allowing egg reduction from 50% up to complete replacement, depending on the formulation.

Kitchen lab trials demonstrated that Lasenor® VP-100 produces muffins with excellent volume, softness, moisture, and overall consumer appeal comparable to full-egg recipes. Beyond muffins, the ingredient performs effectively across a wide range of baked goods, including sponge cakes, pound cakes, and brioches.

Key Advantages of Lasenor® VP-100

Lasenor® VP-100 offers superior water retention, helping baked products remain soft and moist for longer, thereby extending shelf life. It enables partial or total egg reduction while maintaining stable texture, volume, and crumb structure. The ingredient is 100% plant-based, allergen-free, and non-GMO, supporting clean-label formulations. Its neutral flavor profile ensures no impact on taste or other organoleptic properties, while still delivering comparable volume and dome formation.

“Lasenor® VP-100 directly responds to growing consumer demand for plant-based and allergen-free alternatives,” says Viktoriia Kubrakova, Product Manager for Lasenor® VP-100 at Lasenor. “At the same time, food manufacturers are seeking reliable solutions for partial or full egg reduction, particularly given ongoing volatility in egg supply and pricing.”

Egg prices have risen by 50-90% across the EU and approximately 65% in the US, placing significant pressure on manufacturers to identify more stable alternatives. Baked goods such as muffins, sponge cakes, and sweet pastries carrying plant-based claims are experiencing double-digit growth in product launches, driven by demand for more sustainable, ethical, and better-for-you products.

Optimized Muffin Performance

“Lasenor® VP-100 delivers strong functional performance in muffin formulations, helping manufacturers achieve the desired texture, moisture, and structure even with reduced egg content,” Kubrakova adds. “Our trials show that VP-100 integrates seamlessly into standard cake recipes without requiring changes to existing processing methods.”

For optimal performance, Lasenor® VP-100 undergoes a controlled hydration and activation phase, enabling the development of its gelling, binding, and water-retention properties before incorporation with the remaining ingredients. The fully mixed batter is whisked into an aerated structure, where the activated protein enhances foam stability and air retention during baking. The batter is then deposited into 45 g cavity molds and baked for 20 minutes at 180°C (355°F).

“Trials with Lasenor® VP-100 resulted in soft, voluminous muffins with a uniform fine crumb and stable structure,” concludes Kubrakova. “The ingredient also supports key on-pack claims such as ‘100% plant-based,’ ‘egg-free,’ and ‘clean label.’”

Lasenor® VP-100 made its official debut at Fi Europe 2025 in Paris from December 2–4, where Lasenor showcased and offered tastings of muffins reformulated with the innovative texturizing pea protein, both at its booth and during an exclusive afternoon tea event.

About Lasenor:

Lasenor is a global food ingredients specialist with over 20 years of expertise in emulsifiers, stabilizing systems, and functional solutions, particularly for bakery applications. Headquartered in Spain, the company operates production sites and commercial offices across Europe, the Americas, India, and Asia, supporting manufacturers worldwide with tailor-made ingredient systems and hands-on technical expertise.

Lasenor also runs multiple application laboratories and pilot-scale facilities. Its portfolio includes clean-label and plant-based solutions, lecithin, bakery systems, and release agents designed to enhance texture, stability, process efficiency, and product quality, while advancing sustainability through decarbonization, water conservation, and waste reduction initiatives.

Have a news or topic to share with industry? Write to us editorial@pfionline.com