In modern food manufacturing, filtration process has evolved from a background process into a critical force. Mrigank Bothra explores the essential role of filtration, highlighting how it enhances ingredient consistency, air purity, and product safety while strengthening consumer confidence.

In the competitive landscape of food manufacturing, efficiency and safety are not simply operational objectives; they are fundamental requirements. As food factories focus on the enhancement of quality to meet consumer demands, the silent yet powerful, substantial presence of filtration technology is playing an important role. Whether by assuring the consistency of ingredients or the improvement of air quality in manufacturing spaces, where the filtration system has become the primary instrument of reliability, safety, and hygiene in food production.

Ensuring Consistency & High-Quality Products in Food Processing

In food processing, even the most minor variations or complexities in ingredients can cause issues such as changing product texture, taste, and appearance of the food & beverages. Filtration ensures that materials such as sugar, flour, and other powdered ingredients meet precise size requirements before entering production lines. This consistency in process is especially crucial when raw materials are obtained from various procurement regions or from different batches. Sieves and precision filters help to uniform particle size, and that ultimately preserves the look, texture, and quality of the final product, with an essential factor for consumer satisfaction and brand trust.

Safeguarding the Food products with the filtration process

Mainly, beyond the ingredient filtration, where air quality management plays an equally vital role in ensuring product safety. The air circulating within food processing areas must remain free from dust, spores, and microbial contaminants. To maintain this, the Air Handling Unit (AHU) filters and HEPA filters come into operation. AHU filters are used to maintain the circulation of clean air throughout the processing and packaging area. They catch the airborne particles and furnish the space where food is mixed, baked, or packed with a dust-free and sterile environment. HEPA filters are of high efficiency and are the most important in halting microbial contamination in critical areas where products are most susceptible to it. By filtering out 99.97% of particles as small as 0.3 microns, HEPA systems help maintain the final product’s integrity, while safeguarding both consumer health and brand credibility.

Pleated filters are designed with the option of increasing surface area and offering high dust holding capacity. With a capability of maintaining airflow while ensuring filtration efficiency.

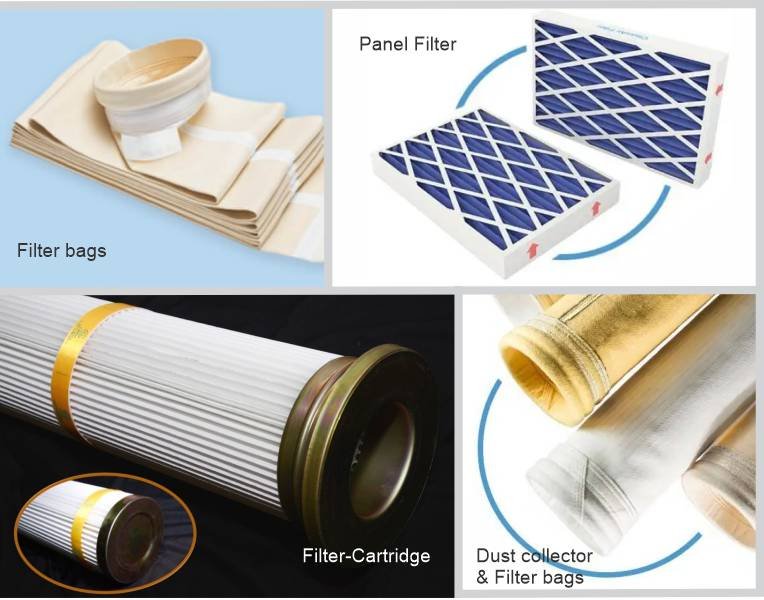

Bag filters are mainly used with a steam boiler, where high dirt removal is critical to processing and cleaning food products. These filters capture larger particles and residues, ensuring the steam remains free of impurities and maintains food safety. While controlling this dust, manufacturers not only prevent contamination but also improve the air quality and worker safety within the plant production.

Cartridge and Panel filters serve dual functions in the filtration chain. Cartridge filters, well-known for their high level of accuracy, are used in liquid or air streams to filter by safeguarding the smaller particulates that get into packaging or bottling. Panel filters, used in pre-filtration stages, help to extend the life of more complex filters downstream while saving operational costs and improving overall system efficiency and process.

Enhancing Efficiency through Smart Filtration

Increasing efficiency in food manufacturing is not just about maintaining speed, but it’s about ensuring every unit of energy and resource delivers maximum output without compromising the quality of food products. Modern filtration systems contribute significantly to this balance and value. They increase production output by preventing equipment fouling, reducing downtime, maintaining steady flow rates, and reducing maintenance interruptions and any failures with real-time systems.

Advanced filtration technologies are now designed for longer service life, with easy replacement and energy efficiency. For instance, pleated and cartridge filters can handle higher dust loads while maintaining airflow, reducing the strain on HVAC systems and lowering operational costs and reliability. When combined with regular monitoring and preventive maintenance, these systems become essential assets for any modern processing facility, as well as for workplace safety.

| Also Read: Combustible Food Dust: A Hazard That Cannot Be Ignored

A Cornerstone of Food Safety

The importance of filtration extends beyond efficiency and is an aspect to win the trust of consumers. Nowadays, with regulatory oversight and customer awareness levels at their peak, producing safe food production is a must. Every filter used to be in the air system, ingredient line, or liquid processing unit, which plays a role in upholding food safety standards set by agencies worldwide. Effective filtration prevents cross-contamination between the ingredients, removes foreign particles, and ensures the absence of allergens and pathogens. Whether it’s in the beverage manufacturing or food packaging, tailored filtration systems protect against impurities at every stage, ensuring that the product reaching the consumer meets uncompromised standards of safety and quality.

Filtration is no longer a behind-the-scenes process, but it is the game-changer of food manufacturing. From sieving raw ingredients to maintaining sterile air conditions and ensuring steam purity, filtration technologies drive every aspect of efficiency, hygiene, and product integrity. The industry’s continued evolution with innovations toward automation and precision processing only strengthens the role of effective filtration systems as an essential component of sustainable, eco-friendly, and safe food production.

As the food manufacturers adopt advanced filtration strategies, the realization becomes evident. With a cleaner environment, consistent quality, safe food, and stronger filtration solutions, it builds a more trusted connection with customers.

💡 FAQs: Filtration Process in Food Manufacturing

Filtration is crucial for maintaining product consistency, removing impurities, and preventing contamination. It ensures that air, water, and ingredients meet strict hygiene and quality standards in compliance with global food safety regulations.

Common filters include sieves, pleated filters, bag filters, cartridge filters, panel filters, and HEPA filters. Each serves a distinct role, from ingredient uniformity to air purity and steam cleanliness.

HEPA filters remove up to 99.97% of particles as small as 0.3 microns, effectively preventing microbial contamination in critical production areas such as packaging and filling zones.

AHUs regulate and circulate clean air throughout the facility. Equipped with advanced filters, they ensure that production areas remain free from dust, spores, and airborne contaminants that could compromise product safety.

Modern filtration systems prevent equipment fouling, reduce downtime, and extend machinery lifespan. They maintain optimal airflow and liquid flow rates, reducing maintenance costs and improving overall productivity.

Yes. Advanced filters like pleated and cartridge filters are designed for high dust-holding capacity and longer service life. They minimize pressure drops, helping HVAC systems consume less energy while maintaining performance.

Filtration ensures uniform particle size in food ingredients like sugar or flour and prevents contamination during processing. This consistency directly impacts texture, taste, and appearance, all vital for consumer satisfaction.

Absolutely. Proper filtration systems prevent airborne or process-based transfer of allergens, dust, or pathogens, helping manufacturers comply with HACCP and ISO 22000 food safety standards.

Regular monitoring, preventive maintenance, and timely replacement of filters are key. Automated filtration monitoring systems can alert operators before performance drops, ensuring continuous safety and efficiency.

With the rise of automation, IoT monitoring, and eco-friendly processing, filtration systems are becoming smarter, more sustainable, and integral to achieving zero-contamination, high-efficiency production lines.

The author is the Director of ClipOn.io, a company specializing in advanced industrial filtration and processing solutions that ensure sustainability across various industries. The company has been recognized by leading organizations such as NAFA and ASHRAE for adhering to the highest standards in filtration and processing.

Have a news or topic to share with industry? Write to us editorial@pfionline.com