A Japanese research team has successfully harnessed E. coli bacteria to create PDCA, a durable, biodegradable plastic substitute. Their method eliminates harmful wastes while achieving record output levels, overcoming major hurdles with innovative solutions.

- SUMMARY

- Kobe University team engineered E. coli to produce pyridinedicarboxylic acid (PDCA), a biodegradable alternative to harmful PET components.

- The process achieved record yields with no unwanted byproducts, overcoming major technical hurdles.

- The innovation opens new possibilities for sustainable plastics and bio-manufacturing.

Plastic is integral to modern life, but its production harms the environment and contributes significantly to global pollution. Now, researchers from Kobe University in Japan have developed a more eco-friendly method for producing a plastic ingredient using living bacteria.

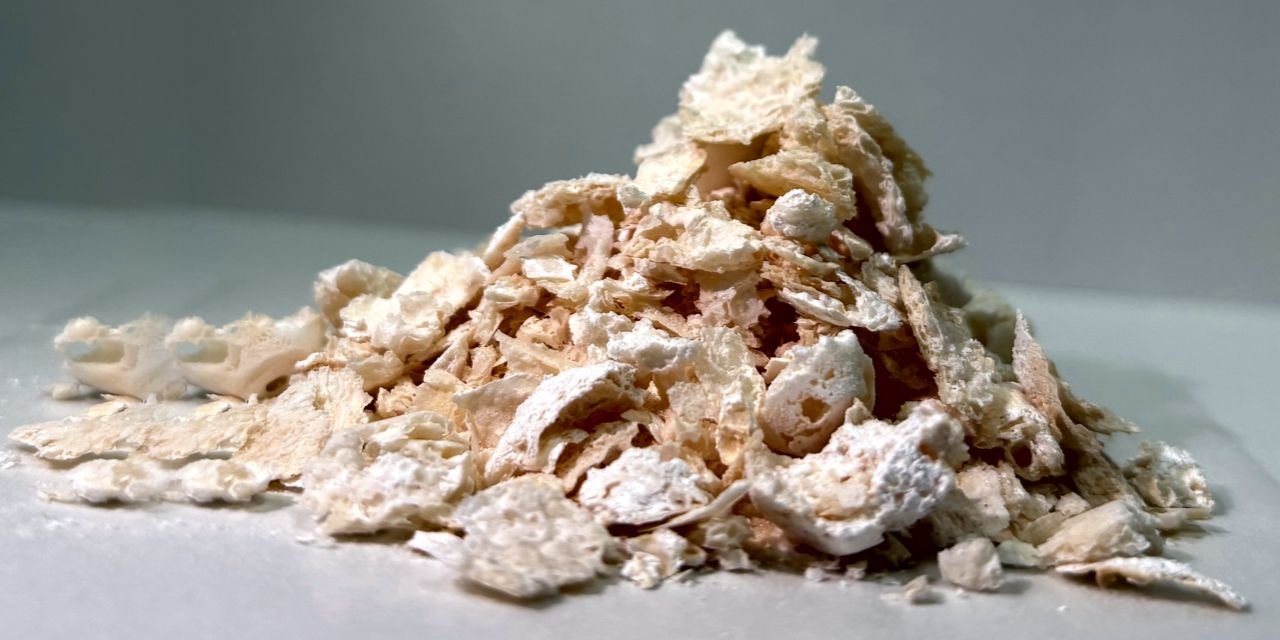

The material, called pyridinedicarboxylic acid (PDCA), is not a complete plastic replacement but can substitute for terephthalic acid, a key component in PET plastics widely used in bottles, containers, and textiles. Unlike conventional counterparts, PDCA is nitrogen-based, biodegradable, and offers superior physical properties.

The PDCA is not only biodegradable but also has superior physical properties. A Kobe University team of bioengineers engineered E. coli bacteria to produce the compound from glucose at unprecedented levels and without byproducts, and opened up a realm of possibilities for the future of bioengineering.

The durability of plastics is both the reason why they have become so widespread and why they pose environmental problems. In addition, they are mainly sourced from petroleum, making them non-renewable and contingent on geopolitics. Research groups worldwide work on both biodegradable and bio-sourced alternatives, but there are often issues with yield, purity, and, as a result, associated production cost.

Kobe University bioengineer Tsutomu Tanaka says: “Most biomass-based production strategies focus on molecules consisting of carbon, oxygen, and hydrogen. However, there are highly promising compounds for high-performance plastics that include other elements such as nitrogen, but there are no efficient bioproduction strategies. And purely chemical reactions inevitably generate unwanted byproducts.”

PDCA, which stands for pyridinedicarboxylic acid, is such a candidate. It is biodegradable, and materials incorporating this show physical properties comparable to or even surpassing those of PET, which is widely used in containers and textiles. “Our group approached the challenge from a new angle: We aimed to harness cellular metabolism to assimilate nitrogen and build the compound from start to finish,” says Tanaka.

In the journal Metabolic Engineering, the Kobe University group has now published that they achieved the production of PDCA in bioreactors at concentrations more than seven-fold higher than previously reported. Tanaka explains, “The significance of our work lies in demonstrating that metabolic reactions can be used to incorporate nitrogen without producing unwanted byproducts, thereby enabling the clean and efficient synthesis of the target compound.”

The group, however, did have some stubborn problems to solve along the way. The most stubborn of these came when they discovered a bottleneck where one of the enzymes they had introduced produced the highly reactive compound hydrogen peroxide (H₂O₂). The compound then attacked the enzyme that produced it, thereby deactivating it. “Through refining the culture conditions, in particular by adding a compound that can scavenge H₂O₂, we could finally overcome the issue, although this addition may present new economic and logistical challenges for large-scale production,” Tanaka explains.

The bioengineers already have plans on how to improve the production going forward, with every problem pointing the way to its solution. Looking at the future, Tanaka says: “The ability to obtain sufficient quantities in bioreactors lays the groundwork for the next steps toward practical implementation. More generally, though, our achievement in incorporating enzymes from nitrogen metabolism broadens the spectrum of molecules accessible through microbial synthesis, thus enhancing the potential of bio-manufacturing even further.”

Despite this, the study shows real progress toward making biodegradable plastics that are more sustainable. The team believes this new method can help reduce reliance on petroleum-based plastics and contribute to solving the plastic pollution crisis.

Have a news or topic to share with industry? Write to us editorial@pfionline.com