Are you planning to start a potato chips factory? This guide walks you through every essential step. From setting up the factory and estimating costs to understanding licenses, processes, and equipment, you’ll find it all here.

Potato chips are one of the most popular ready-to-eat snacks. People across age groups enjoy them regularly. With urban lifestyles getting faster, the demand for packaged snack foods like chips is rising steadily.

Table of Contents

Why Potato Chips Manufacturing?

Potato chips are one of the most consumed snack items globally. In India, the market for chips is expanding rapidly due to urbanisation and rising disposable income. The rise in the number of players in the Indian food processing industry reflects this growing opportunity.

According to the Ministry of Agriculture, India is expected to produce around 59.57 million tonnes of potatoes in 2024–25, a significant increase. This growth is driven by expanding investments in storage and processing infrastructure.

Uttar Pradesh and West Bengal lead in potato production and cold storage capacity. Together, they account for over half of the country’s total storage infrastructure. It’s estimated that 80–85% of harvested potatoes are stored in cold facilities, helping reduce wastage.

Potatoes aren’t just consumed as vegetables. They are the base for many value-added products like chips and potato powder. Among these, chips are the most in-demand product in India.

There are two major categories in the chips market:

- Branded Chips – Examples include Lay’s, Pringles, Ruffles, Uncle Chips, and Haldiram’s.

- Local/Non-branded Chips – These operate regionally and cater to retail as well as institutional buyers.

If you’re looking to start a food business with low investment and high demand, potato chips making is a smart choice. It needs limited capital and space. Plus, it’s great for retail distribution.

10-Step Guide to Start a Potato Chips Factory

Step 1: Analyze the Market for Potato Chips Business

Before jumping in, spend time understanding your local and regional snack food market. Look into what flavours are popular—classic salted, masala, peri-peri, etc. Check if people prefer thick or thin-cut chips, or even baked varieties.

Visit local shops, supermarkets, and speak to restaurant and snack vendors. Also, research what branded and non-branded chips are selling. Don’t forget to explore the export potential—India regularly exports chips to countries like the USA, UK, UAE, and Australia. All this data will help you tailor your product and strategy effectively.

Step 2: Prepare a Business Plan to Setup Potato Chips Factory

Your business plan is your roadmap. The business plan serves as a blueprint for initiating and running the business smoothly. Depending on your production output, you will need to craft a financial analysis. Additionally, clearly state the mission and vision of your company.

It also helps you stay focused and is essential when seeking loans or investors. It should include:

- Mission & vision – What problem are you solving, and what’s your long-term goal?

- Target market – Who are your customers? Local consumers, retailers, or bulk buyers like caterers?

- Cost estimation – Cover land, equipment, raw materials, salaries, utilities, and marketing.

- Revenue forecast – Estimate how much you’ll make monthly and yearly.

Example Costs (for 130 MT/year capacity):

- Land & Building: ₹20 lakh (can reduce by renting)

- Machinery: ₹10.5 lakh

- Raw materials, salaries, utilities: ~₹6.85 lakh (monthly)

Also include marketing strategies—offline promotions, digital ads, referral programs, and product sampling.

Step 3: Arrange Finance for Start a Potato Chips Plant

One of the biggest concerns of small-scale manufacturers is cost. You may explore government subsidy schemes for food processing units to ease initial financial pressure.

It’s better to start the business with the financial assistance of the bank. Also, you can propose to the venture capitalist for funding your project. Apart from the project finance, banks also offer machinery hypothecation or cash credit facility for working capital assistance only. For the entire project finance, you need to furnish the machinery quotation. The bank may also ask for the owner’s contribution and collateral security.

Once your plan is ready, explore funding options:

- Bank Loans – Apply for term loans (for equipment) and working capital loans (for running expenses).

- Government Schemes – Check MSME schemes that offer subsidies or low-interest loans.

- Private Investors – You can also pitch to angel investors or small VCs interested in food startups.

To qualify for funding, keep your documents ready: project report, machinery quotations, business registration, and, in some cases, property or collateral proof.

Step 4: Choose the Business Structure for Potato Chips Production

Initiating a potato chips production facility requires company formation. Generally, banks prefer LLP or Pvt Ltd organisations to a sole proprietorship firm for giving loans. However, you will need to choose the right form of organisation according to the investment pattern of your company.

Decide how you want to legally structure your company:

- Sole Proprietorship – Simple, but banks may not prefer this for large loans.

- Partnership or LLP – Ideal if you have co-founders or investors.

- Private Limited Company – Best for scalability and gaining investor trust.

If you’re planning to start small, a proprietorship is okay. Just get a Trade License and GST registration. For LLP or Pvt Ltd, register with the Ministry of Corporate Affairs (MCA).

Step 5: Complete Registrations and Licenses for potato chips manufacturing unit

To ensure food safety and legal compliance, getting familiar with the FSSAI registration process is crucial. It provides your business with the legitimacy and trust required in the competitive food sector.

After the company formation, you will need to register for MSME Udyog Registration online. It helps in getting Govt subsidies. Apply for the Trade License from the local Municipal authority. Apply for the FSSAI license. To get the ISI mark, you will need to obtain BIS registration. And in that case, you need to comply with the quality control protocols. Obtain an NOC from the state Pollution Control Board. Secure the company brand name by registering the Trademark. Finally, get the GSTIN for the regular tax payment.

This step ensures your business is legal and protected. Here’s what you need:

- Udyam/MSME Registration – For access to subsidies, bank loans, and govt benefits.

- Trade License – From your municipal authority.

- FSSAI License – Mandatory for food businesses to ensure safety and hygiene.

- BIS Certification (optional) – Needed if you want to sell with an ISI mark.

- Pollution Control NOC – Especially if your plant produces smoke or waste.

- Trademark Registration – To protect your brand name and logo.

- GSTIN – Required for invoicing and tax compliance.

Step 6: Choose Right Location Potato Chips Production facility

In starting any type of food business, you must be careful in site selection. Don’t select a site near harmful chemical factories. Also, you need to ensure the electricity and water supply. This type of production process requires an adequate water supply. Generally, you need 20 HP power for the machinery operation. Check the nearby transport facility. Also, you can consider having space in an industrial zone.

Pick a location that’s clean, food-safe, and well-connected. Keep these in mind:

- Avoid areas near chemical or heavy manufacturing units.

- Ensure access to clean water and steady electricity (20 HP power minimum).

- Good road access helps with raw material delivery and product distribution.

- If possible, choose an industrial zone—it’s easier to get licenses there.

Step 7: Set Up the Production Unit for Potato Chips

After selecting the space, you will need to draw a floor plan. Ask the machinery supplier to provide the machinery installation plan. And accordingly, craft the factory plan. Determine a specific place for the raw material storage, finished goods storage and space for official work.

Now that you have the location, design a proper layout:

- Raw materials area – Clean and dry, separate from production.

- Processing zone – Install equipment as per workflow (washing → slicing → frying → packing).

- Storage – One area for finished goods, another for packaging materials.

- Office/Admin space – Small area for paperwork, computer, and supervision.

Request a factory layout plan from your machinery supplier—they often offer this for free.

Step 8: Buy Machinery and Equipment for a Potato Chips Pant

To produce 120 to 150 MT of potato chips, you need a small-scale setup. And if you want a larger production line, then you can go for a fully automatic process. Here is a list of basic machinery requirements.

You’ll need specific machines based on the size of your operations. A semi-automatic line is a good starting point. Here’s the essential list:

- Potato washer & peeler – Speeds up initial prep.

- Slicing machine – Ensures uniform chip thickness.

- Blanching unit – Softens and pre-cooks the slices.

- De-watering machine – Removes excess water before frying.

- Fryer – The heart of the operation. Choose an oil-efficient model.

- De-oiling unit – Removes surface oil from chips.

- Flavouring drum – Mixes spices and seasonings.

- Packing machine – Vacuum or nitrogen flushing to keep chips fresh.

Always buy from trusted suppliers and check warranties, spare part support, and installation assistance.

Step 9: Source Raw Materials

Raw materials are readily available throughout the country. Mainly, you need good-quality potatoes. Try to procure potatoes with good shape. Other consumables you need are edible oil, spices, salt, flavours, and packaging consumables. Packing plays a vital role here. You will need to provide moisture-free packing for retail consumption. Also, provide cartoons for bulk supply.

The main ingredient is potatoes—but quality matters.

- Choose clean, uniform-sized potatoes with fewer “eyes” (less wastage).

- Other materials include:

- Edible oil (sunflower or palm oil)

- Seasonings, spices, salt

- Packaging film (airtight, food-grade)

- Cartons (for transport and bulk orders)

Buy in bulk to save costs. Build relationships with farmers or wholesale suppliers.

Step 10: Master the Potato Chips Manufacturing Process

The process of making chips involves washing, peeling, slicing, frying, and flavoring the potatoes. It’s vital to understand the role of food processing machinery in ensuring efficiency and consistent product quality.

First of all, procure good-quality potatoes. Select the potatoes that have the minimum number of eyes to cut down the losses by trimming. The next step is washing and peeling. You can do it either manually or by using machines. Place the potatoes in the water to prevent browning.

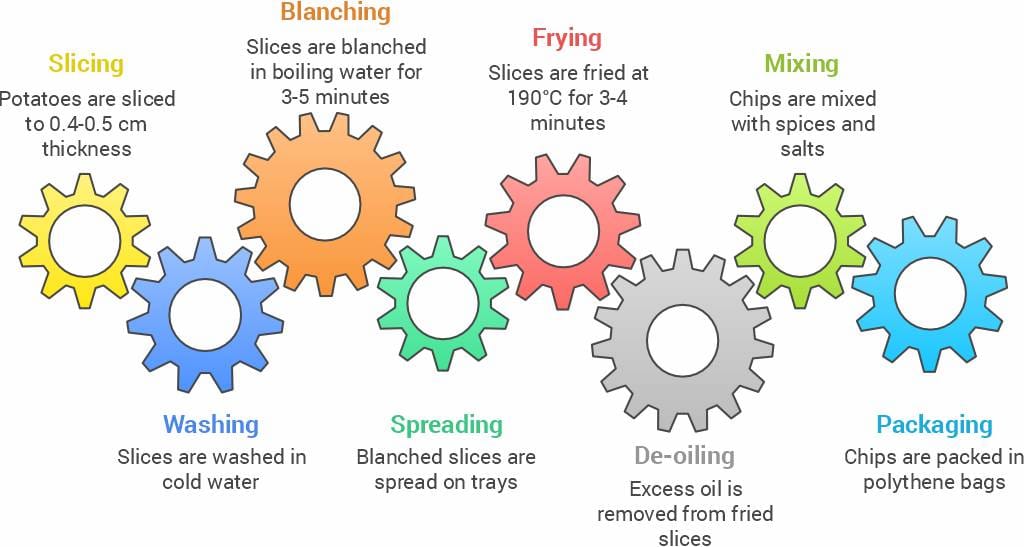

Slice the potatoes in 0.4 to 0.5 cm. thick in a slicing machine. Again, place the slices in cold water. Blanch the slices for 3 to 5 minutes in boiling water and spread on trays at the rate of 4.88 kg. to 7.30 kg. per square metre of tray surface. After the de-watering, fry them at 190°c for 3-4 minutes. Keep the fried potato wafers on the sieve to remove excess oil. After cooling, mix the other ingredients like salts, the spice mixture as per required taste. Finally, pack the cooled potato chips in polythene bags and seal.

Here’s a simple breakdown of how chips are made:

- Slicing: Using a slicing machine, slice the potatoes to a thickness of 0.4 to 0.5 cm.

- Washing: Place the potato slices immediately in cold water.

- Blanching: Blanch the slices in boiling water for 3 to 5 minutes.

- Spreading: Spread the blanched potato slices on trays at a rate of 4.88 kg to 7.30 kg per square meter of tray surface.

- Frying: After de-watering, fry the potato slices at 190°C for 3-4 minutes.

- De-oiling: Place the fried potato wafers on a sieve to remove excess oil.

- Mixing: After cooling, mix the potato chips with other ingredients like salts and the spice mixture according to the desired taste.

- Packaging: Finally, pack the cooled potato chips in polythene bags and seal them. Use nitrogen-flush packs for longer shelf life.

Additionally, packaging plays a critical role in maintaining freshness and market appeal. Opt for innovative and eco-friendly options aligned with the latest food packaging trends.

Label the packs clearly with MRP, manufacturing date, expiry date, ingredients, and FSSAI number.

Final Tips for Success

- Start small, test your product locally, and gather feedback.

- Focus on quality—stale or oily chips can kill your brand.

- Build your brand on social media. Offer free samples to stores and tea stalls.

- Monitor oil reuse—don’t compromise on health or taste.

- Think about adding baked or multigrain chips later to expand your product line.

Have a news or topic to share with industry? Write to us editorial@pfionline.com